Senasic cutting-edge technology: High reliability, high precision — Resistive dual-channel sensor interface chip SNU511

This issue introduces the newly launched resistive dual-channel sensor interface chip SNU511 by SENASIC. SNU511 is designed for high-precision amplification of differential bridge sensor signals and sensor-specific calibration.

Compared to several previous products in the USI product line, SNU511 can simultaneously interface with two resistive bridges. It supports digital compensation for offset, sensitivity, temperature drift, and non-linearity. Calibration coefficients and configuration data are stored in non-volatile memory (NVM), and it also supports overvoltage and reverse connection protection up to ±40V, making it more reliable in automotive applications.

SNU511 also operates within a wide temperature range of -40°C to 150°C, possesses excellent electromagnetic compatibility, and offers various diagnostic functions, making it suitable for harsh automotive environments.

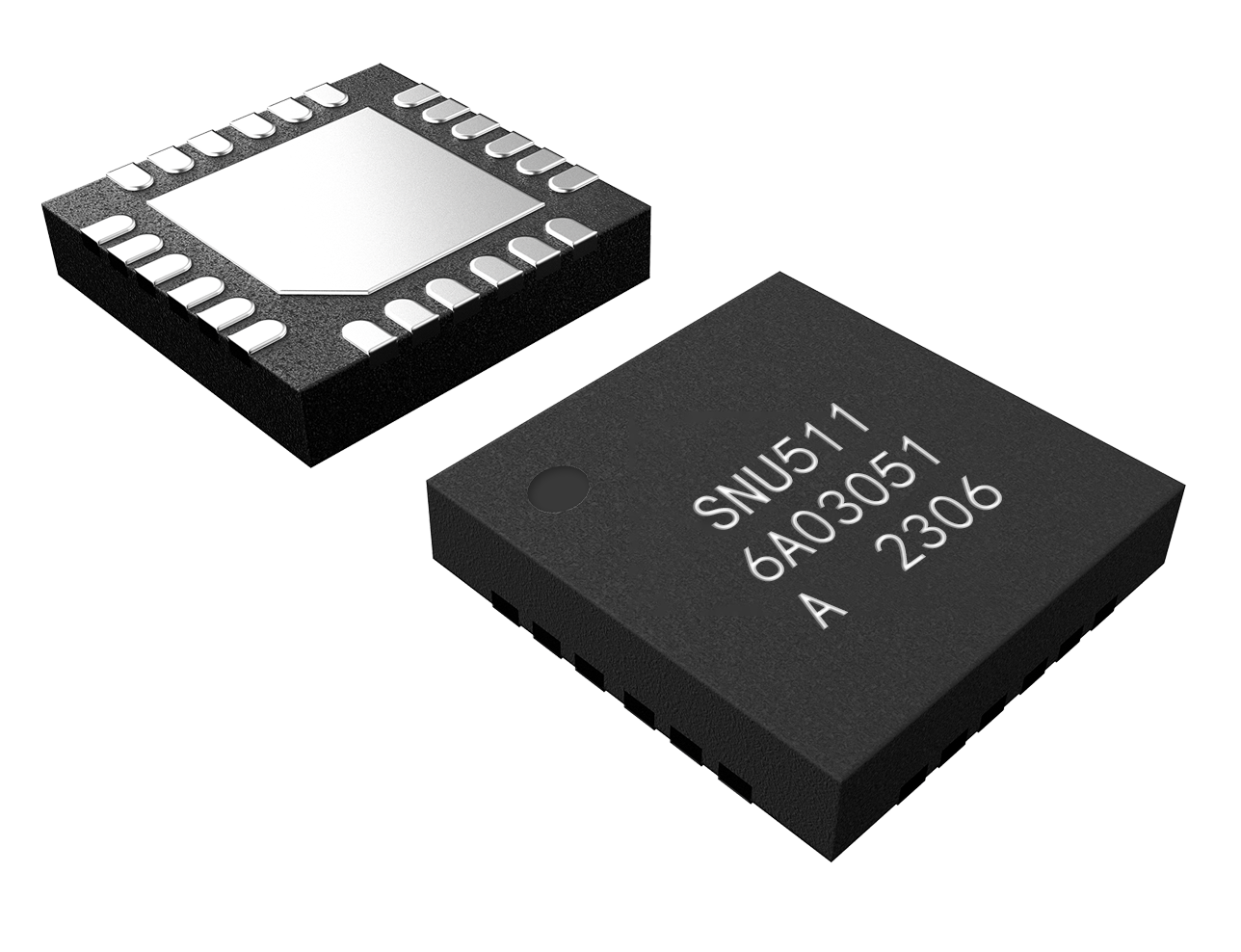

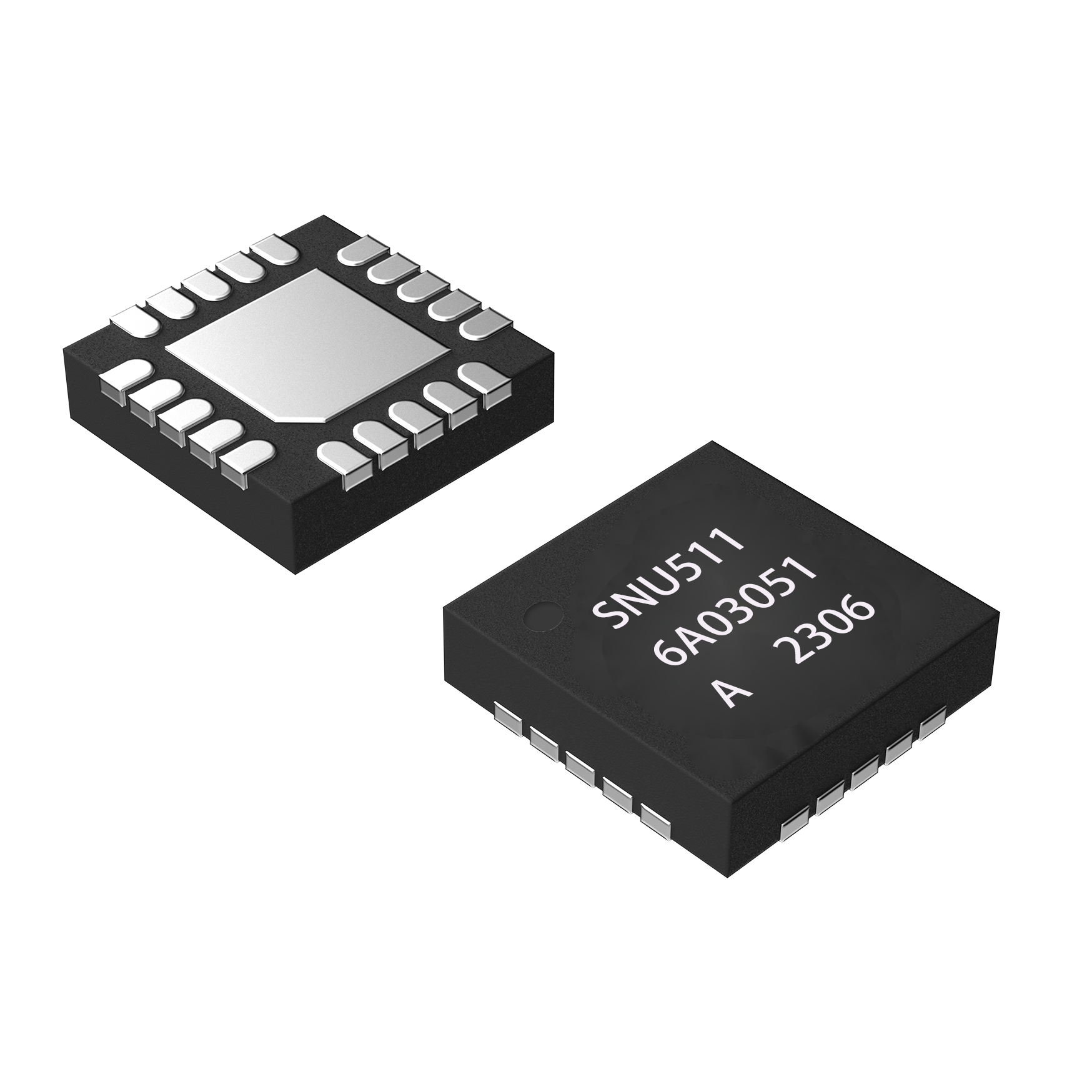

Package

Working principle

The circuit of SNU511 consists of analog front end, digital signal processing, communication interfaces, and output interfaces, etc.

The analog front end (AFE) comprises a multiplexer (MUX), programmable gain amplifier (PGA), and analog-to-digital converter (ADC). The multiplexer (MUX) selects signals from bridge sensors or selected temperature sensors and sends the input signals to the analog-to-digital converter ADC in a defined sequence. The input signals come from:

Bridge sensor elements

Selected temperature sensors

Diagnostic voltage levels

The interface chip supports digital compensation for offset, sensitivity, temperature drift, and non-linearity. Calibration coefficients and configuration data are stored in non-volatile memory (NVM). The measured values are provided as ratio analog output signals at the OUT pin.

Application circuit

Simultaneous connection of two full-bridge MEMS.

Application scenarios

he new universal sensor interface chip SNU511 introduced by SENASIC can simultaneously connect to two MEMS, outputting absolute pressure from both MEMS via SENT or one absolute pressure and one differential pressure.

Its main applications in automobiles include:

Fluid brake pressure sensors

Hydraulic sensors (such as steering systems with hydraulic steering function)

Pneumatic pressure sensors (such as air brake systems, pneumatic shock absorbers)

Features

Power Supply Voltage: 4.5V~5.5V

Wide Operating Temperature: -40°C~150°C

Accuracy: ±1.0%FS @ -40°C~150°C

Bridge Sensor Input Span: 1~800 mV/V

? Memory: 256Bytes EEPROM, supports repeated erasing and writing

? Overvoltage and reverse connection protection: ±40V

? Developed following ASIL C process

? Complies with AEC-Q100 Grade 0 standard

For more product information and requirements for complementary development tools, please contact SENASIC technical support at info@senasic.com.

* Some images are sourced from the internet. If there is any infringement, please contact us for removal.